SISTEC designs, develops and produces automated robotized systems for manufacturing processes.

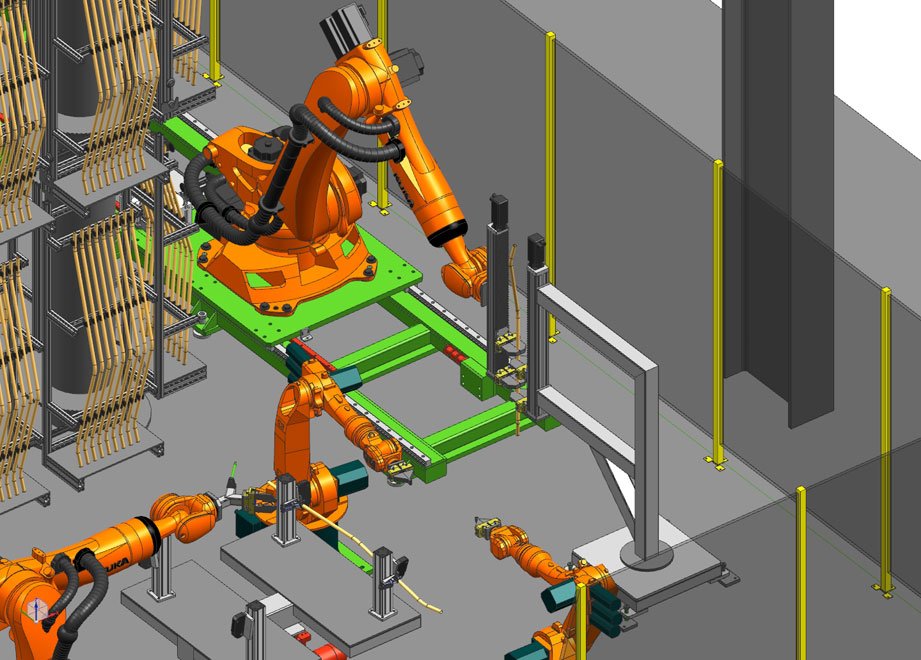

In the bending field Sistec designs, develops and produces: Robotic bending cells that allow to reach high standards, and provide an high production efficiency. The systems are calibrated on actual need of the customer, thus reducing to a minimum cycle time of pieces frequently bent, providing parametric programs for products that are made in different sizes, ensuring minimum setup and adding programming software offline for users which have great variable batches.

The guidelines developed by Sistec for assembly include: Assembly Lines robotized controlled by one or more cooperating robots that assemble components made of multiple components, managing one or all stages of production: feeding and positioning, timing, assembly, marking, testing, packaging and final palletizing. Robotized assembly Lines operated and implemented with vision system that allow picking of elements arranged in bulk in a box or checking their characteristics.

In logistics and palletizing field Sistec can offer the following solutions: customized for end of line Palletizing Logistics. High-speed palletizing plants with different solutions of grip accordingly to the different types of products. Management of changing batch with automated robot retooling. Solutions with robots guide capable of verifying the exact point of product positioning. Solutions with vision system to check the quality of product.

In the welding field we are able to develop and design welding systems with the traditional technologies, but also the new and most recent welding technique, like laser welding which are now having a rapid spread. We can choose the solution more suitable to the Customer needs, no matter if TIG process, MIG/MAG or Plasma, and of course the recent one laser. We offer robotized welding cell or complete welding line systems if need with three-dimensional vision system with laser scan which identify and define the welding path.

The costant rise of productivity demands that the current manufacturing industry need processing on more shifts and even with shifts in absence of operators; Laser cutting machines, both with the traditional CO2 and the more recent fibre technology, belong to those cutting process which better match with the automated loading and unloading systems. If then, as more often happening on the production departments, there is the common issue of limited room, the solution of the tower is the more appropriate and convenient. The main feature of the tower is that it is lifted upon the laser, there is no need of extra-room.

The different processes that, are part of a manufacturing processes, are primary activities; there are anyway some activities which are thought being secondary but are likewise importants and necessaries. An efficient and accurate automation of these activities, it would allow to improve the productivity, organize properly all departments and reduce operating costs. We have the right know-how to design and manufacture every plant tailored to the Customer need for handling applications, pick and place and serving machine.

Contact us for further information about our services and solutions.

Request a free quote.