SISTEC along with his business partner, has developed a series of innovative solutions for the places of cutting the leather, technical articles, plastic and composite materials.

This system is suitable for medium size pieces and for cutting in high volumes; is designed to meet many industries including the field of automotive and lounges.

Since 1993, year of fundation, our main goal was to offer our customers some valid "solutions". Initially we specialized in the field of textile and apparel, by offering CAD systems for size grading and CAM systems for automatic cutting. The products we offer have always represented the highest quality available on the market, because the passion that leads us, together with the continuous search for our clients' satisfaction, have always been the "fixed idea" of our Company.

Following the requests coming from the market, we looked for some alternatives to the apparel industry. Sistec starts dealing with leather, offering a state-of-the-art system for managing and cutting this material using the advanced water-jet technology. This way we entered other markets such as upholstery and automotive and finally boasting among our customers the most important brands in those markets.

The everlasting search for new technologies and the curiosity that takes us exploring new markets brought us to enter the fields of technical materials, starting a collaboration with a German company that produces CAD/CAM systems for cutting materials for the industries of gaskets, packaging, coverings and other.

The changing that occurred on the market pushed the industries to delocalize their production in some take-off Countries, but meantime keeping the design and development of models and prototypes in the head-offices. This situation allowed us to supply these companies with CAD systems, but also to search for some innovative solutions. Since 2005 we started distributing an advanced "body-scanning" system, particularly indicated for those companies who decided to bet on "made-to-measure" apparel.

The following step was for us a real challenge. The know-how gained in all these years allowed us to design, produce and sell our own leather cutting system. This machine was designed as a modular system, in order to satisfy every production need. The experience derived from so many years of collaboration with some of the most important brands worldwide, finally let Sistec introduce itself to the customers with its own brand and logo.

For all the above-mentioned reasons we regard ourselves as an agile, dynamic, innovative and versatile company. Every day we continue our unceasing evolution and expansion, by offering up-to-date products, which are ideal to satisfy all production needs of our customers and are the result of a long experience and a deep knowledge of the different realities. We improved and reinforced the distribution and service departments and enlarged the number of services we offer, in order to be always a qualified partner for your business. Every customer's need is our priority.

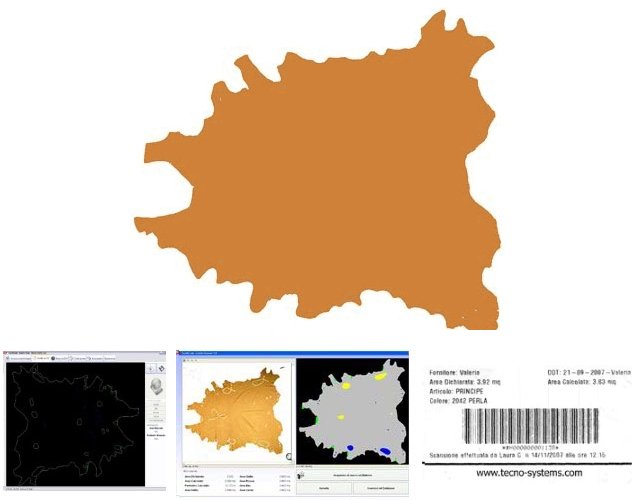

Scanvision

ScanVision, is a virtual digitizer to scan the leather. It acts as a standard digitizer, but much more quickly and accurately. Following debit signature of defects and quality areas by the operator, ScanVision obtains the digital image of the leather by a cameras system and stores it for later use, printing a bar code to be applied to the leather itself . The software is also able to automatically calculate the exact surface of the leather allowing a quick comparison with the data stated by the supplier, for a cost optimization.

Caratteristics

Table dimensions: 3x3 mt.

Camera height: 2,5 mt

Patscan

Patscan is a scanning system for patterns that allows hi-res acquisition of the shapes in a very accurate and fast way (much quicker than a normal digitizer). Pat Scan is easy to use and does not need any particular preparing of the patterns, because the operator just has to position them on the scanning surface and the camera, which is on the frame above the table, takes the picture. Through an efficient algorithm the software is able to recognize automatically all the details such as contours, lines, corners.

Thanks to its large table, it is possible to position also big patterns, made of various materials (paper, carton, plastic, etc.) After that it is possible to insert, move, add or cancel lines or notches on the scanned image, or make any modification on the patterns. The user can determine the quality zones on the patterns. The system is supplied with personal computer and software license.

Caratteristics

Scanning table: 1,5 x 2,25 mt.

Compatibility with many CAD systems and plotters on the market

Export of DXF files

KoriumJet is a water jet system, specifically designed for managing the whole cutting process of leather. What the market needs today is a modular product, which is able to adapt to all specific exigencies: what we meant to realize is a versatile and flexible system, that aims at getting the best quality of production, a steady control of the data, together with extremely low maintenance costs. This way we can satisfy different sectors, from apparel to upholstery, from automotive to boat industry, from leather goods to leather shoes.

Beyond leather KoriumJet can offer complete solutions for the cutting of many kinds of materials, among which gaskets, laminates, technical textiles and materials. KoriumJet is available in three versions: the first with only one cutting table and one cutting head; then the version with two tables and one head, and finally the big one which has got two tables and two waterjet heads. Depending on the specific needs of the Clients and the kind of production, there is the possibility to customize these measures. All above was made keeping a stable structure and a modern design. KoriumJet is extremely simple to use, customizable thanks to its modularity, and in the meantime it is able to offer a working accuracy at the highest level. According to the Customer’s needs the system can be supplied in its on-line or off-line configuration.

Benefits of the system:

- High modularity;

- Optimised and improved production;

- Reduced production costs;

- Constant data check and analysis;

- Very low waste;

- High cutting speed;

- Granted quality of the output;

- User-friendly and easy accessibility for operator;

- CE certified.

Contact us for further information about our services and solutions.

Request a free quote.