TITOLO PROGETTO:

SISTEC Srl: “La massima digitalizzazione nel controllo di gestione.”

DESCRIZIONE:

Il presente progetto è volto all’implementazione di soluzioni tecnologiche innovative finalizzate all’aumento del grado di digitalizzazione aziendale e all’efficientamento del sistema gestionale e del ciclo produttivo interno. In particolare, si intende investire su sistemi di gestione aziendale più innovativi, strumenti di business analytics nonché sulla sicurezza informatica interna.

OBIETTIVO:

Sistec intende portare avanti un percorso strategico di crescita e potenziamento aziendale, sia in termini di sviluppo internazionale sia di avanzamento tecnologico dell’offerta. Nello specifico Sistec, grazie a questo progetto, vuole raggiungere i seguenti obiettivi:

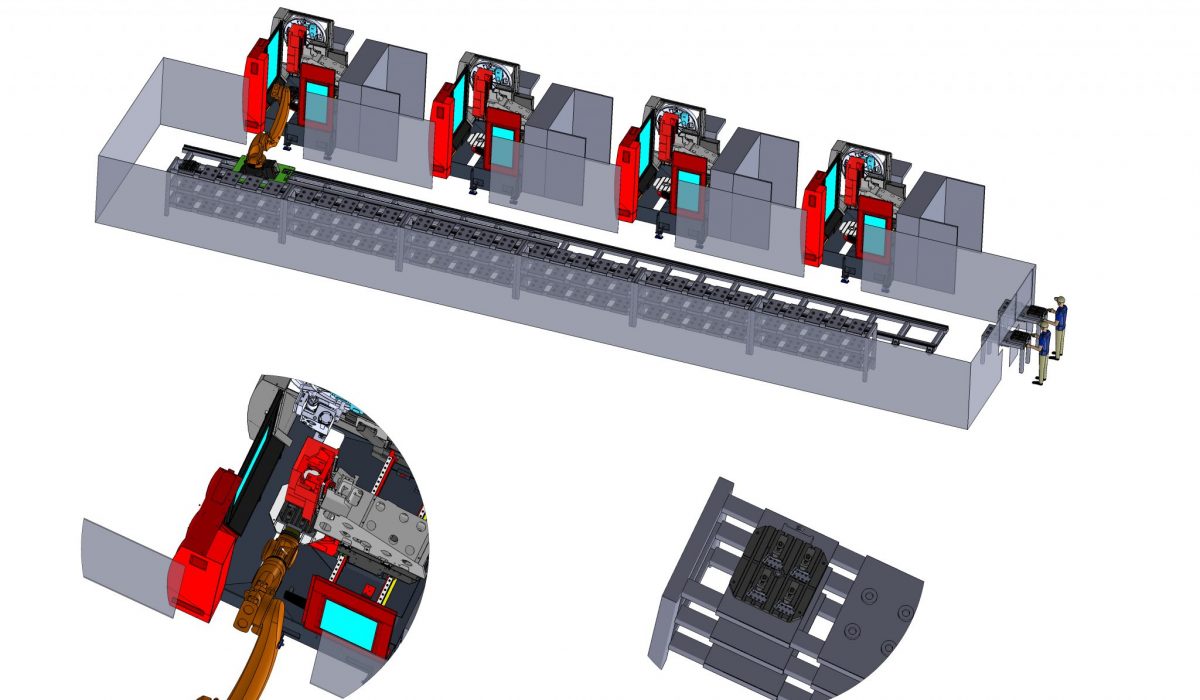

- Realizzare macchine intelligenti, massimizzando il livello di automazione dei propri prodotti;

- Sviluppare tecnologie di progettazione integrata in grado di ottimizzare il processo di realizzazione degli impianti realizzati per conto del singolo cliente.

RISULTATI:

Sistec grazie al presente progetto potrà realizzare una personalizzazione tale da consentire al gestionale di estrapolare e elaborare dei dati fondamentali per la business analysis. Lo scopo è quello di ottimizzare il monitoraggio della marginalità attraverso innovativi strumenti informatici di controllo di gestione delle singole commesse.

CONTRIBUTO CONCESSO:

15.195,00 euro